The pharmaceutical R&D institute includes a full set of processes from API R & D, preparation R & D, quality study and international registration application, and has a postdoctoral mobile station, so it can well ensure the R & D landing of the project.

We have a high level R & D team with more than

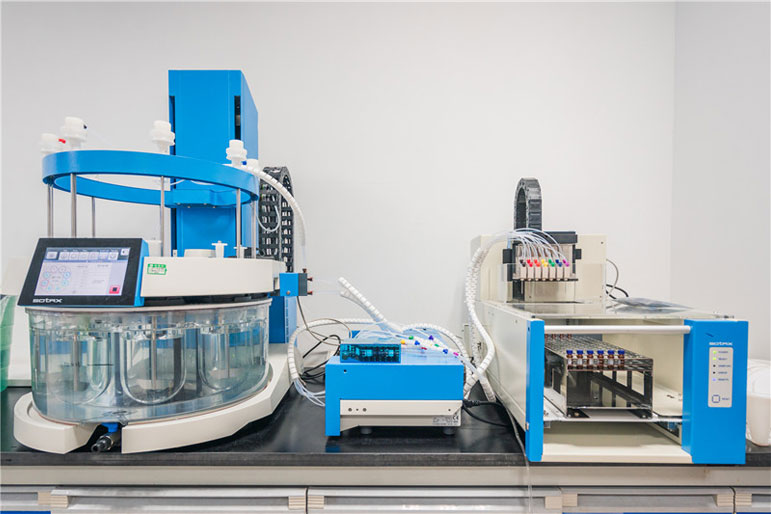

The annual R & D investment is about 8-10% of sales in the year, which provides continuous financial support for cultivating high-level R & D talents and improving R & D equipment.

We are devoted to improve R & D competitiveness by continuous optimized and integration, We have established technical platforms for microchannel reactions, enzyme catalysis and sustained and extended-release.